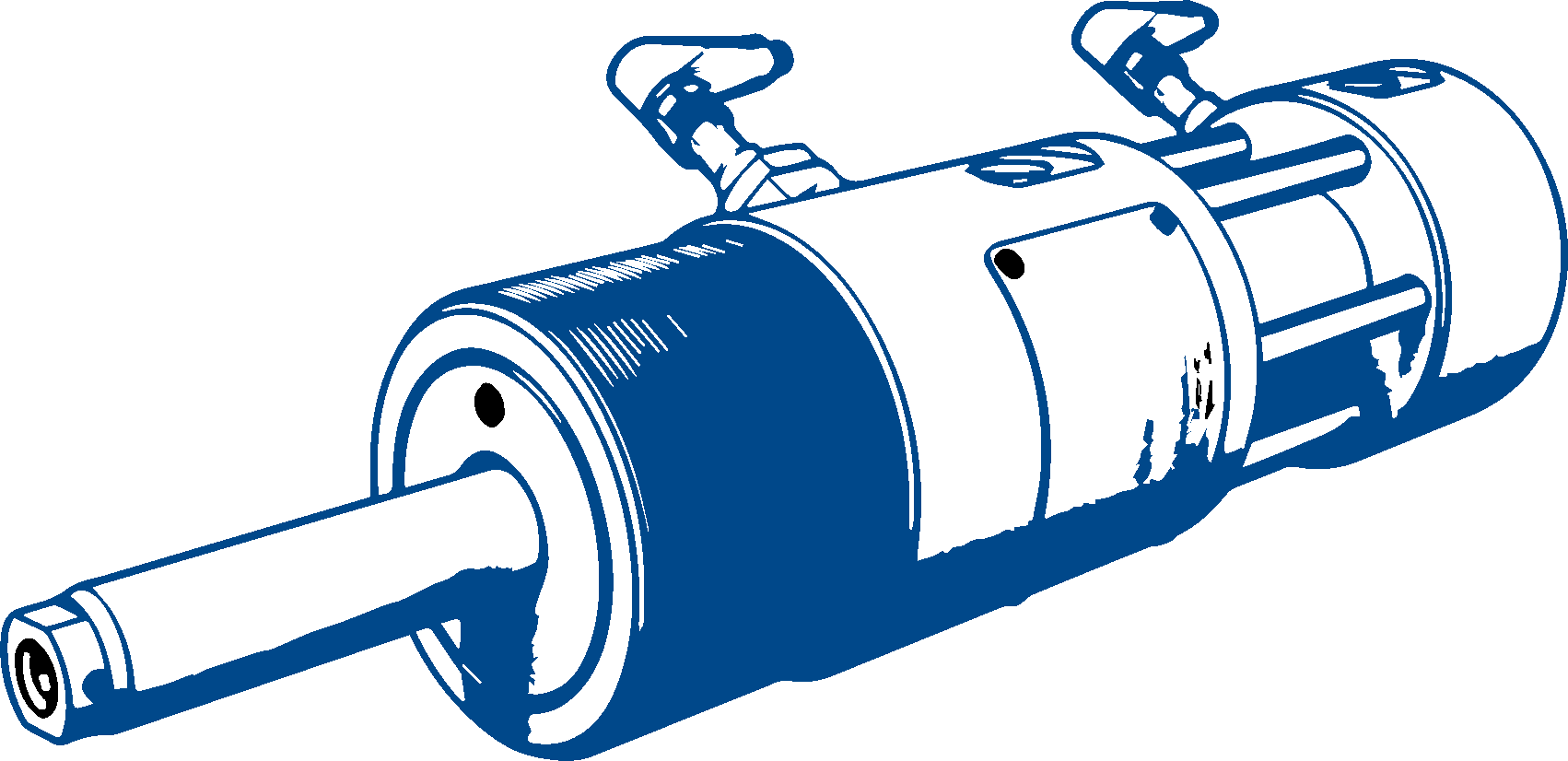

Cylinder technology

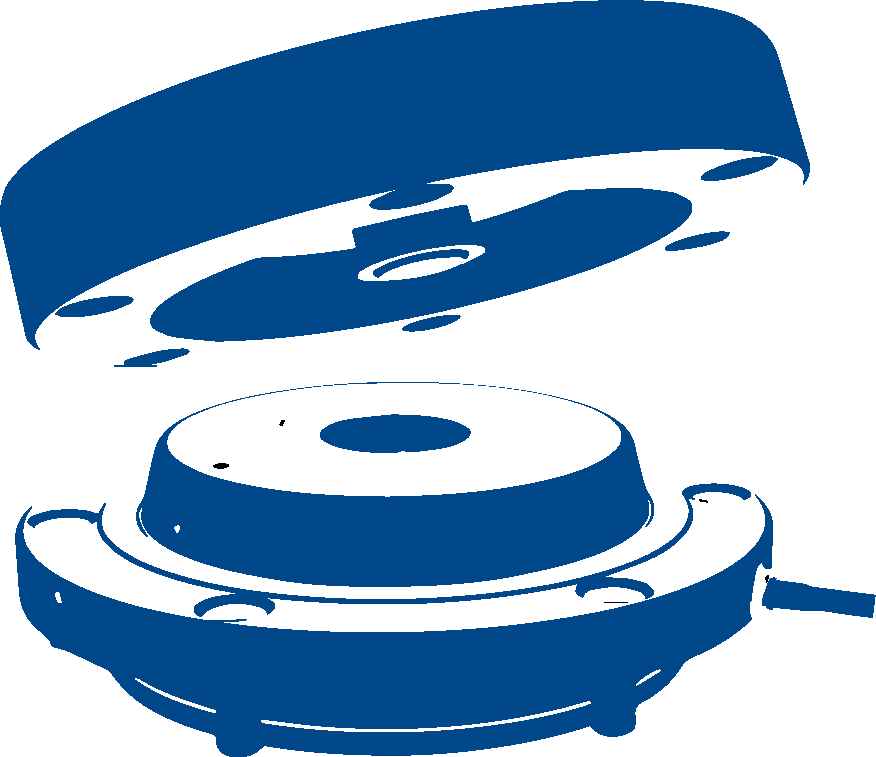

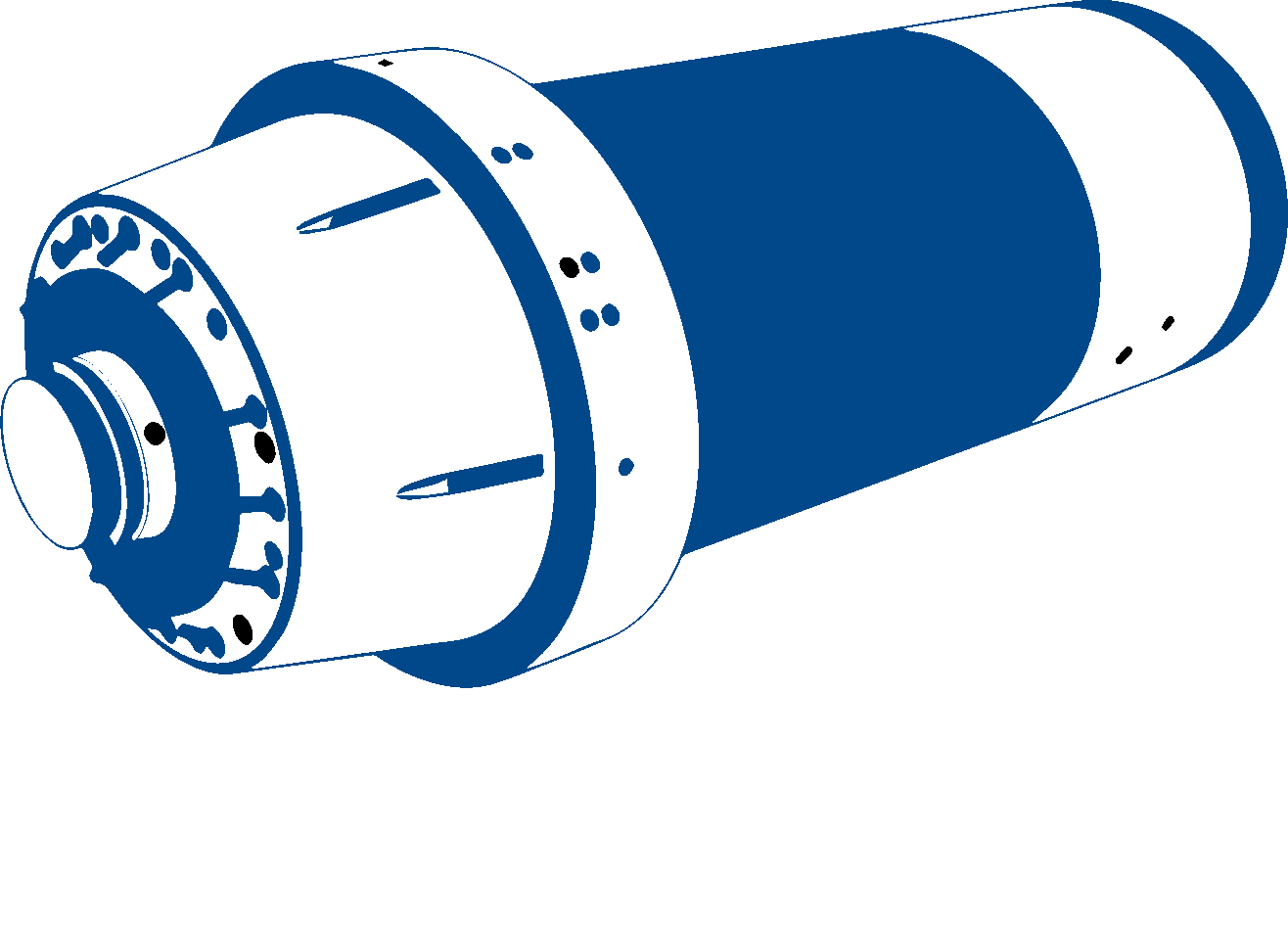

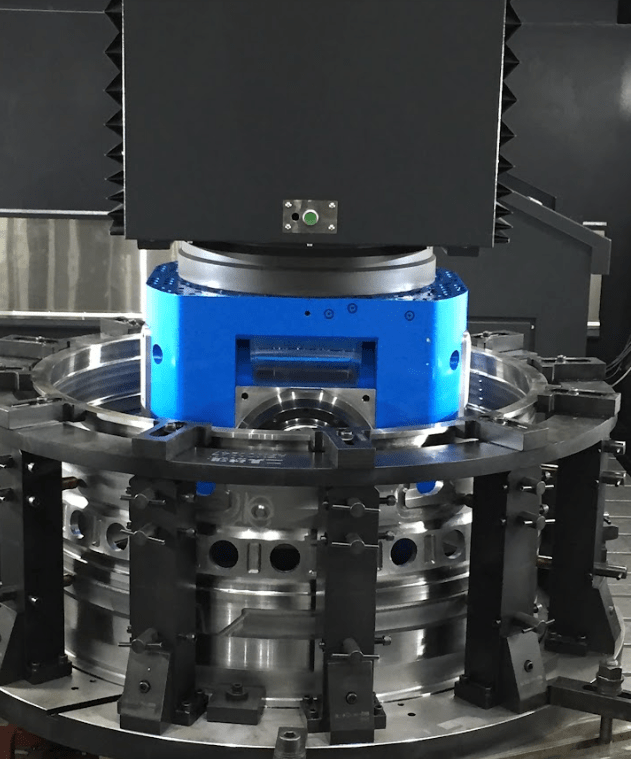

Clamping Systems

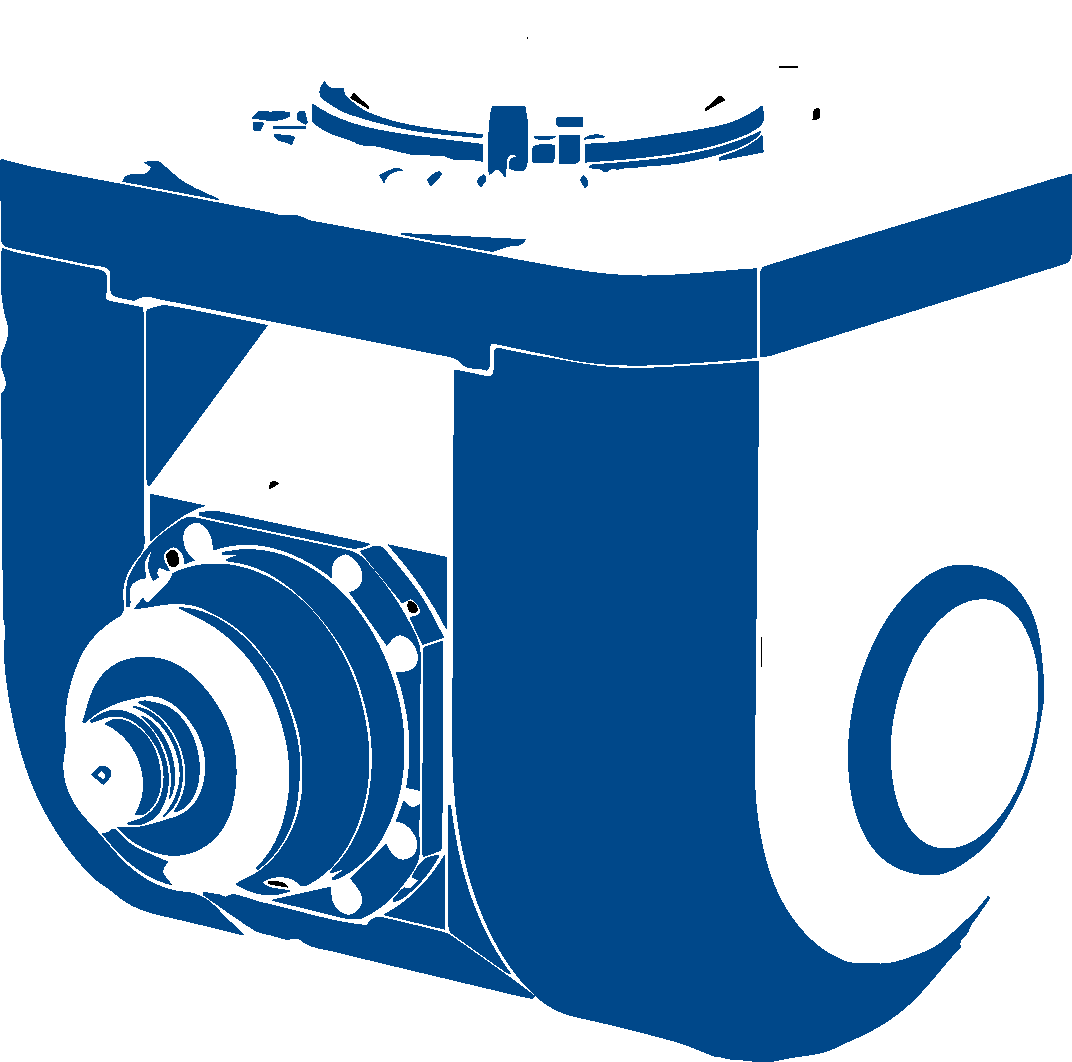

Milling Head

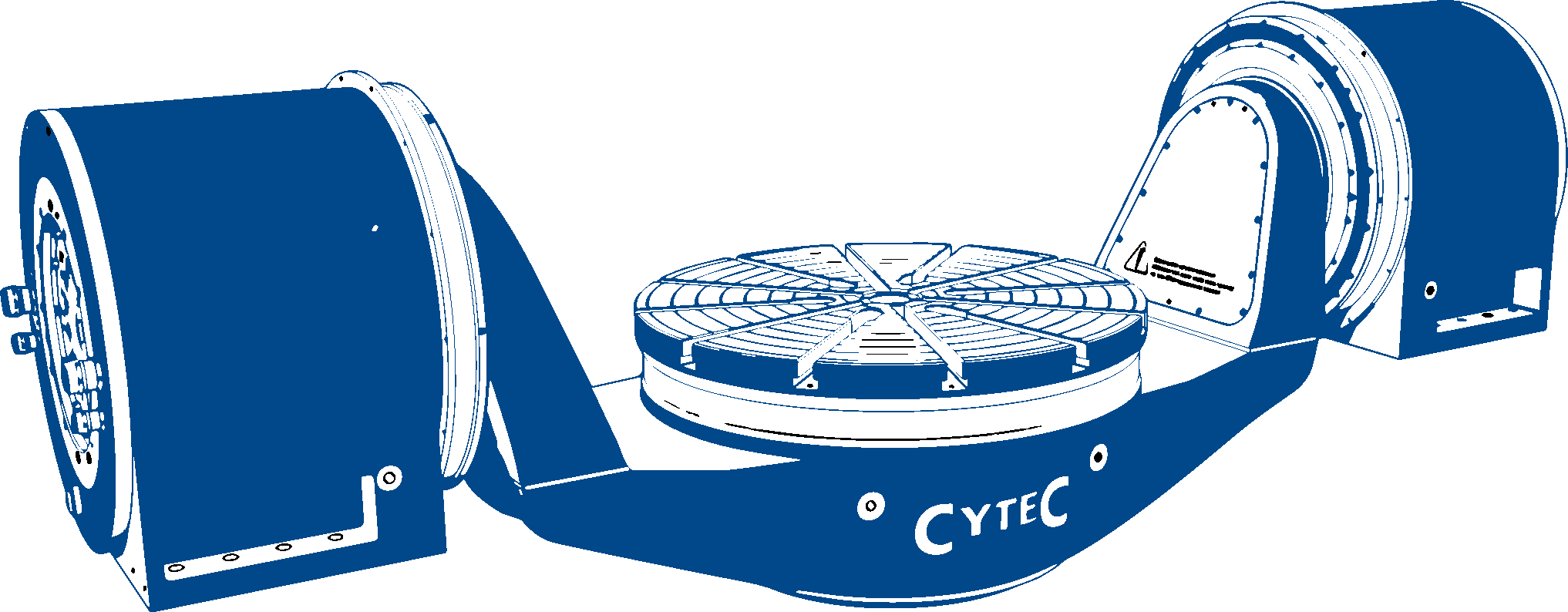

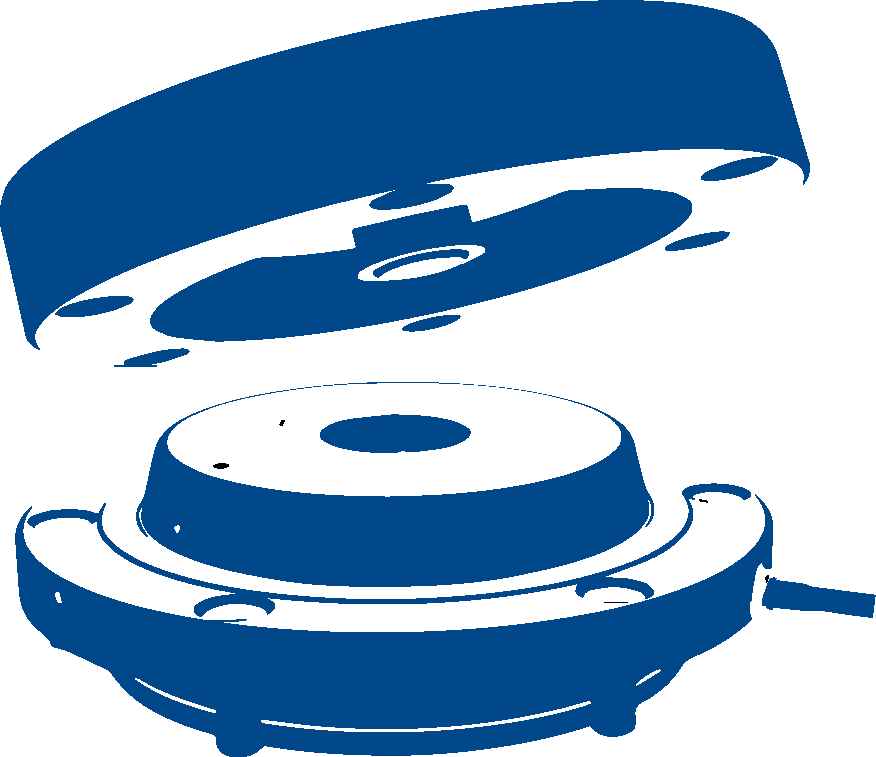

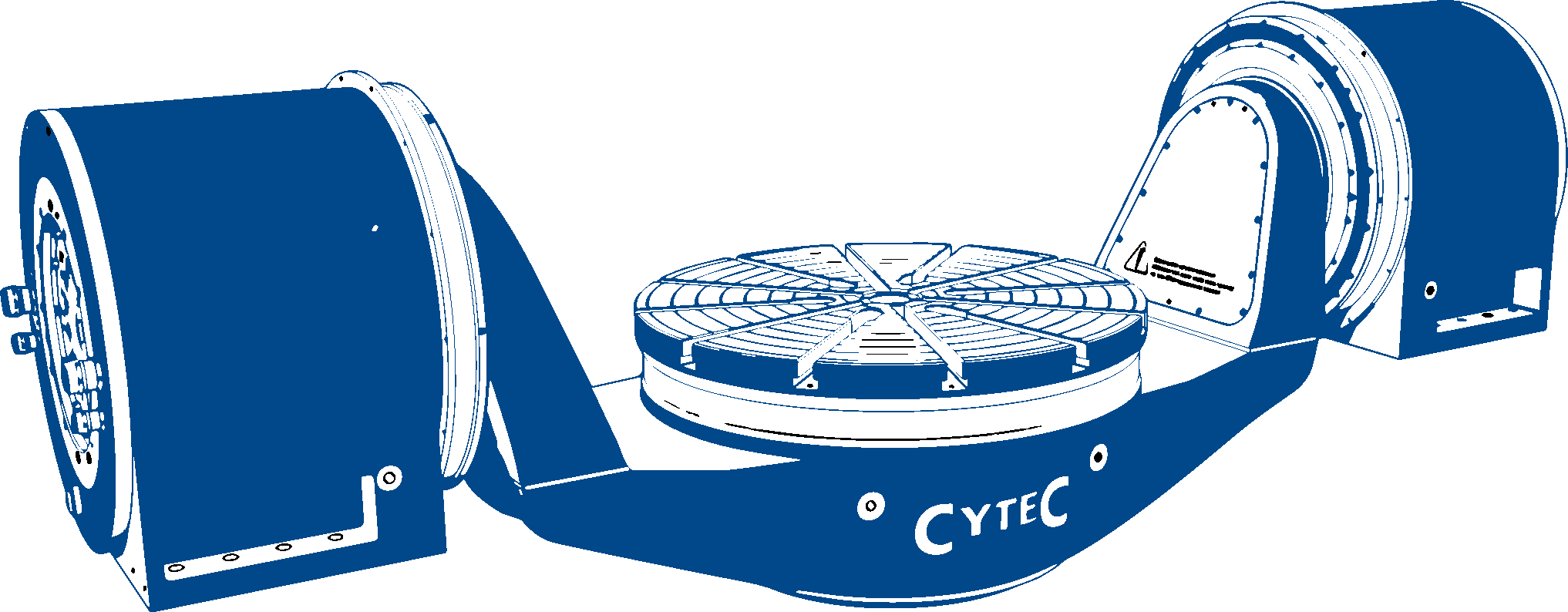

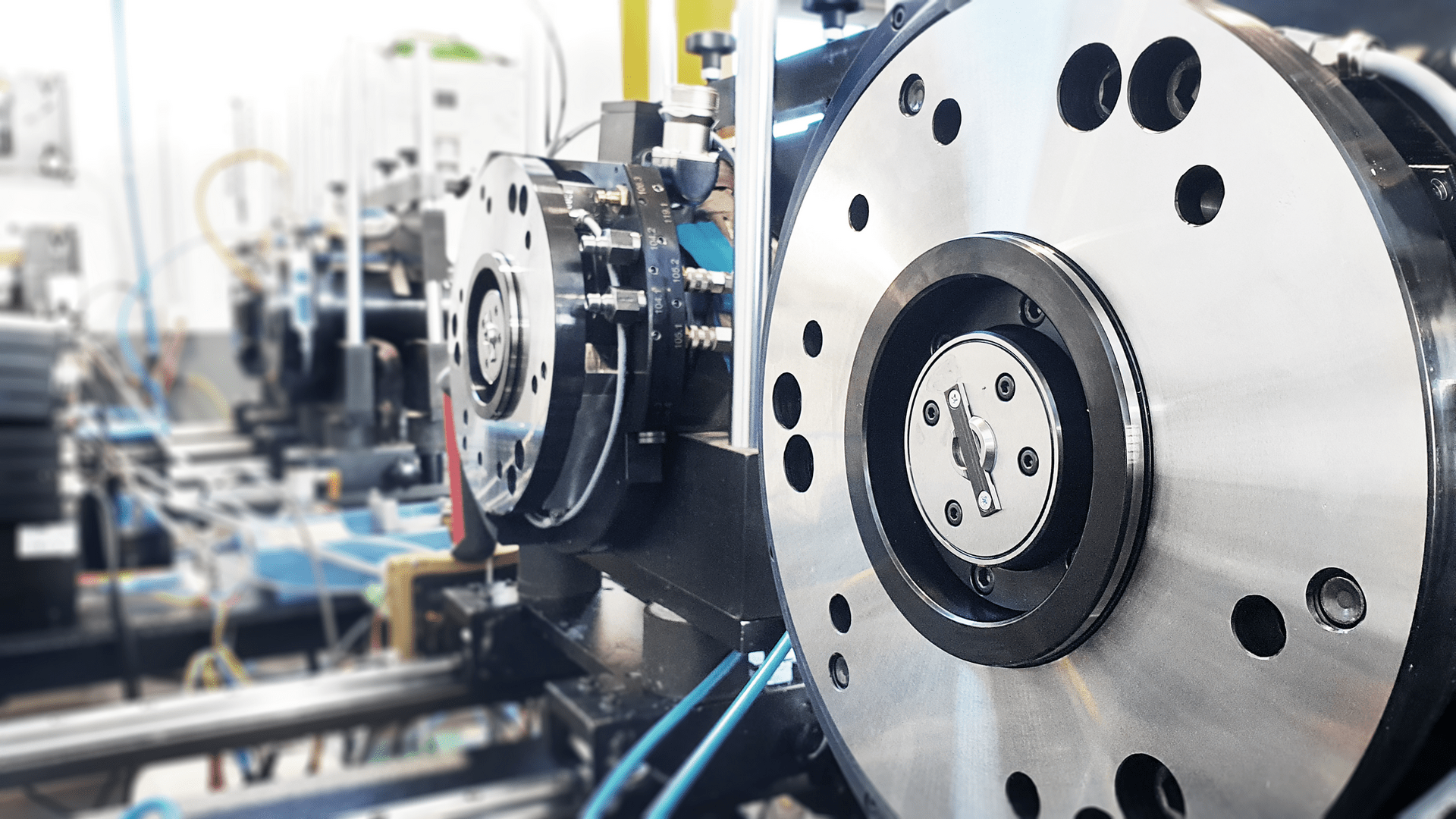

NC Tables

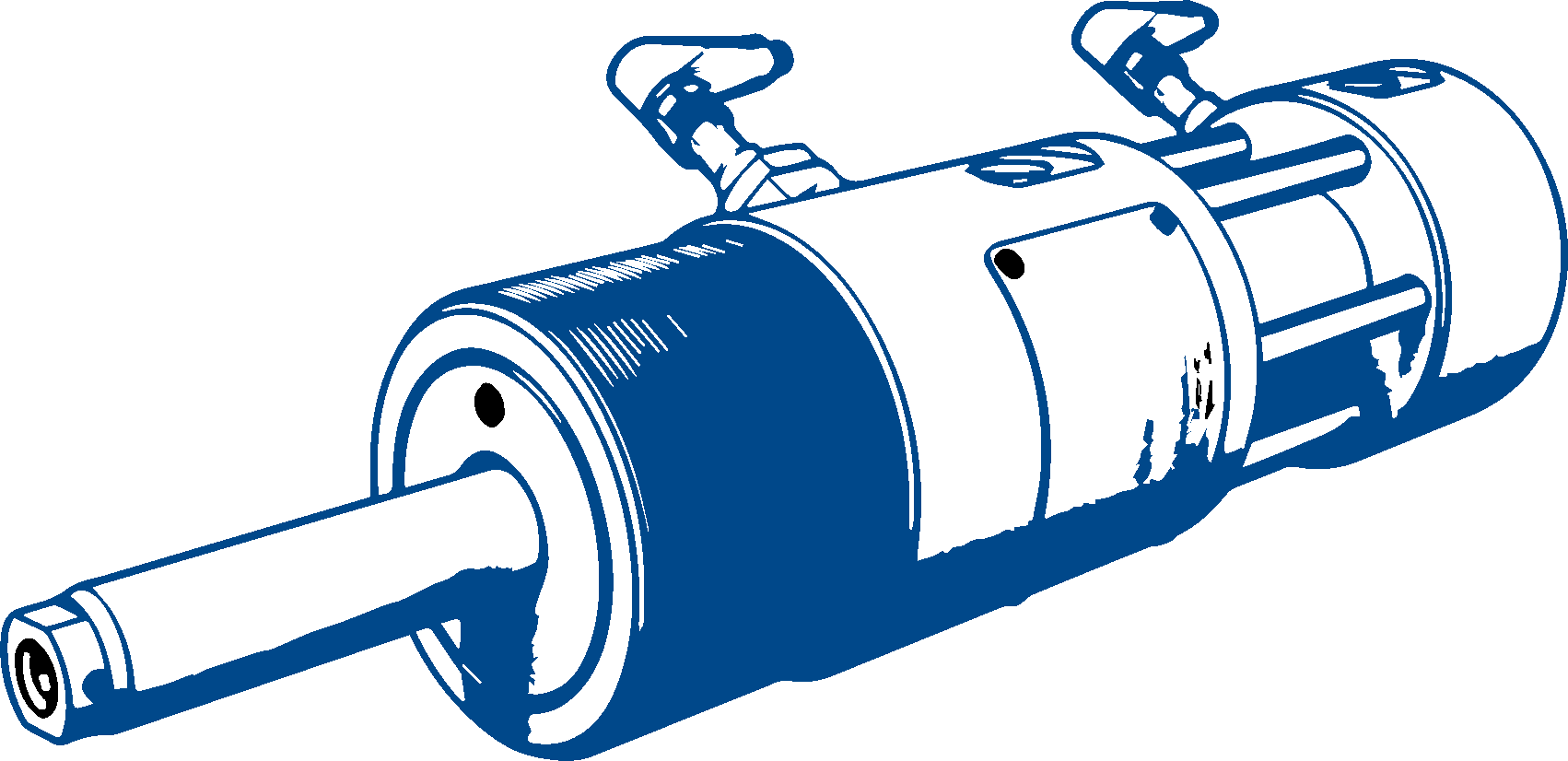

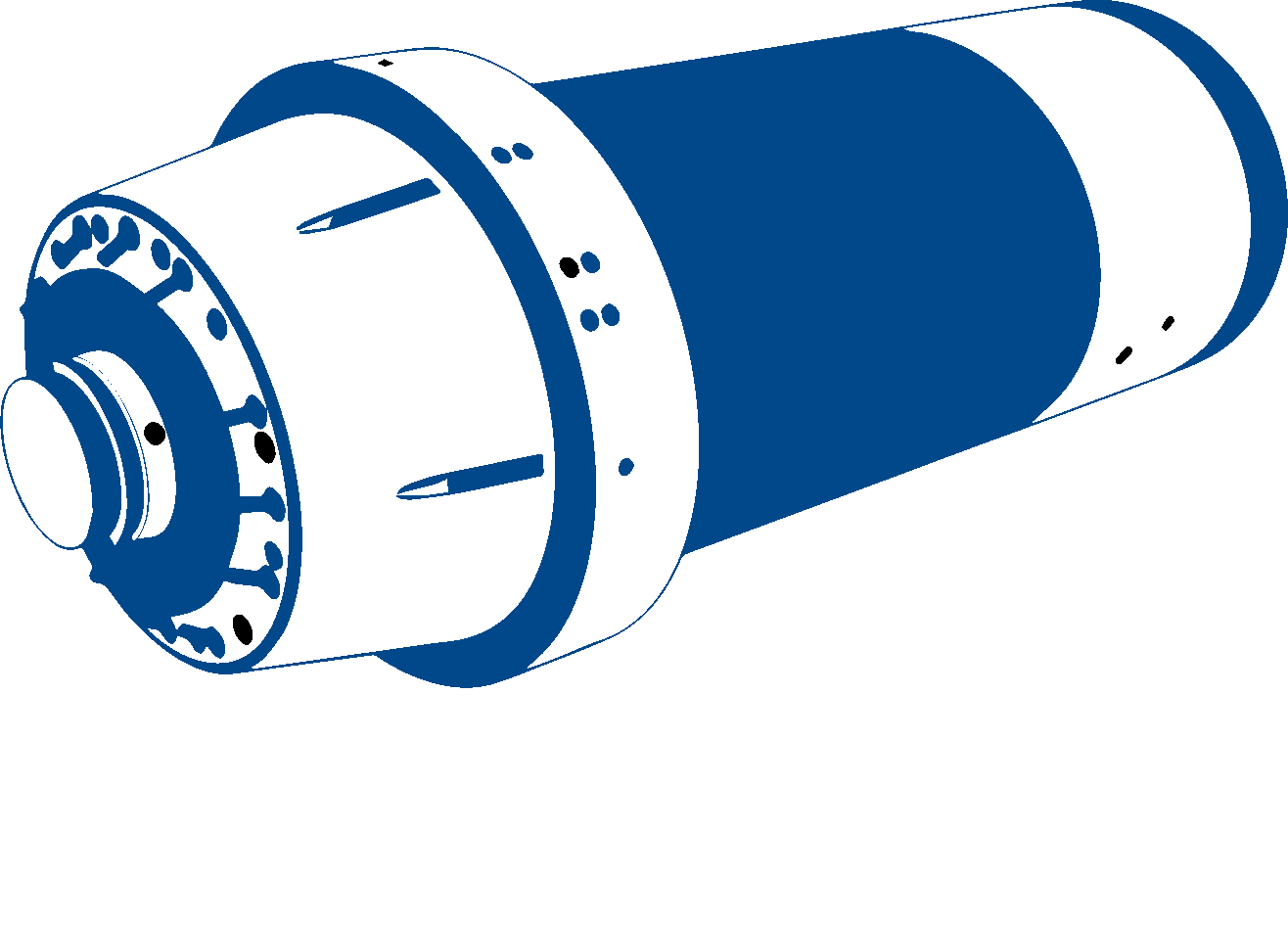

Motor SpindLE

FSW

PROCESS STABILITY RELIABLE DYNAMIC STRONG

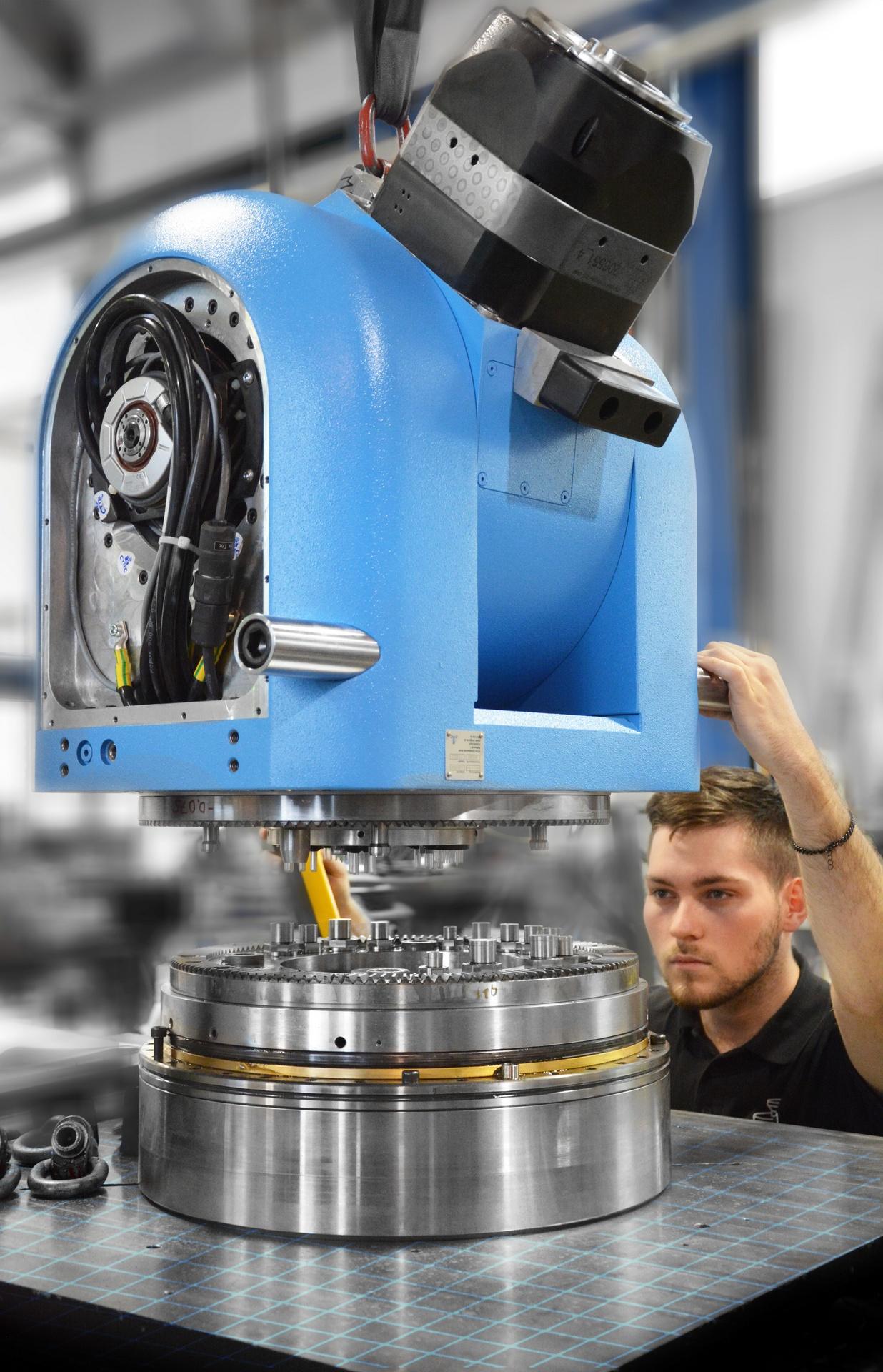

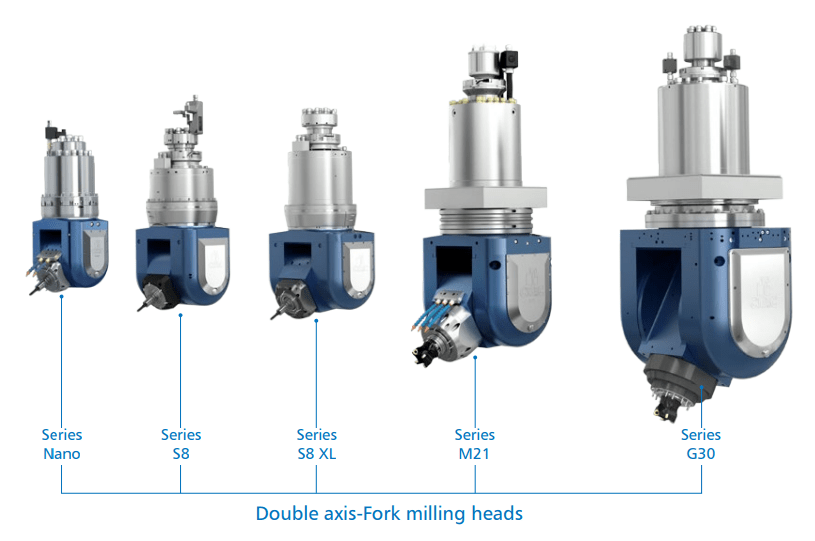

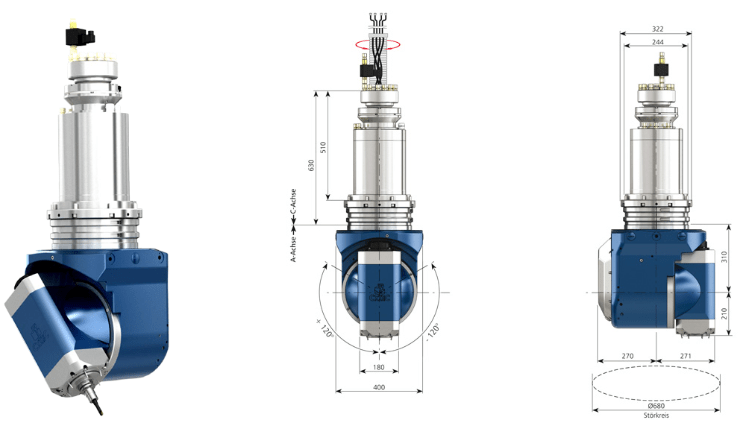

Fork Milling head

has the ability to simultaneously position the cutter in space. This is achieved by controlling the A-axis and the C-axis simultaneously. By combining the movements of the two axes, the Fork Milling head can position the cutter in any desired position in space, allowing for complex and precise cuts to be made on the workpiece.

This type of cutter is particularly suitable for the production of complex tools and shapes where high precision and flexibility is required.

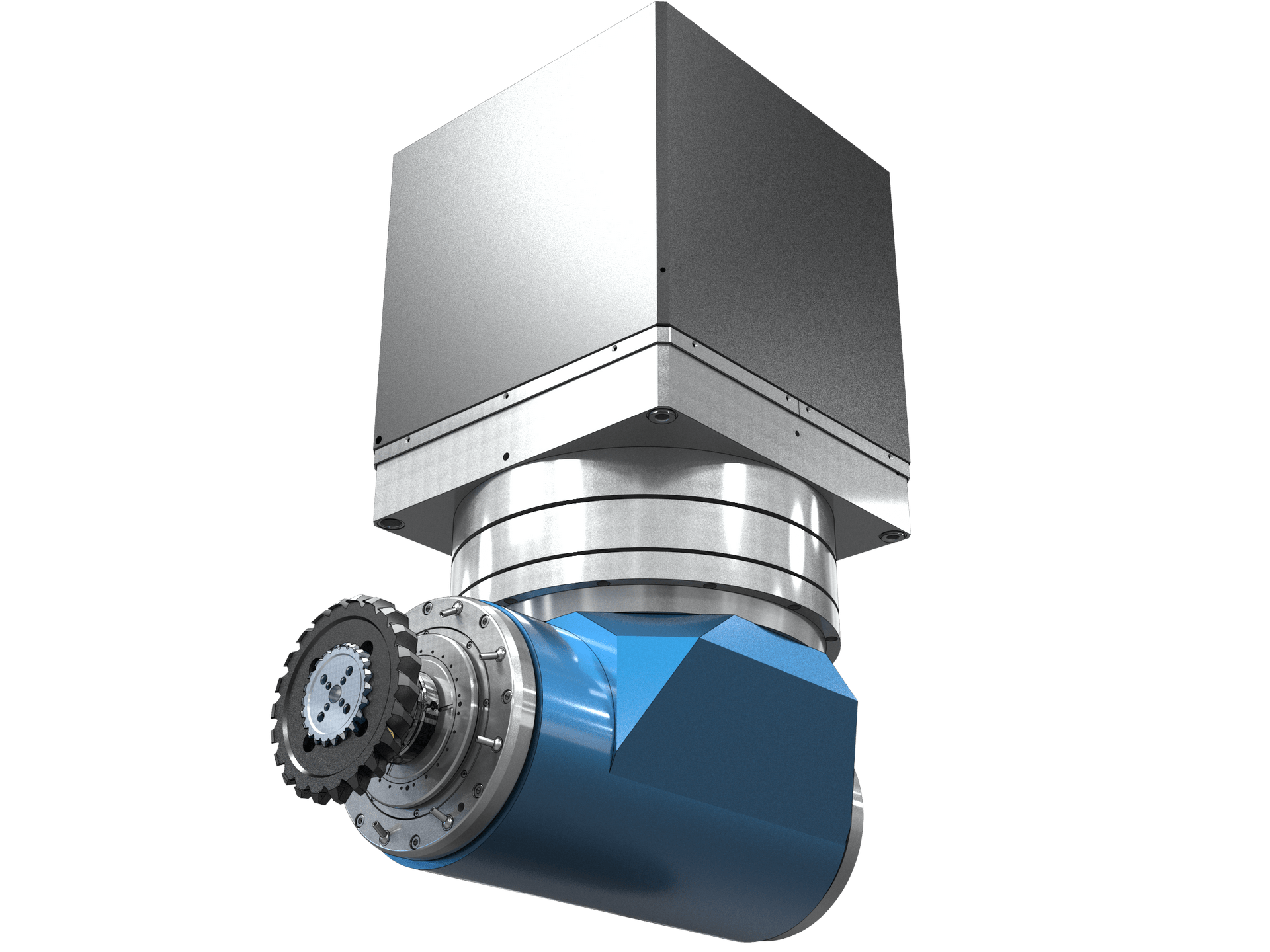

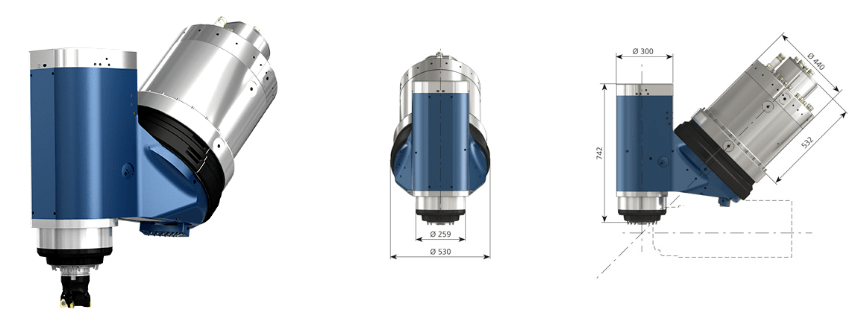

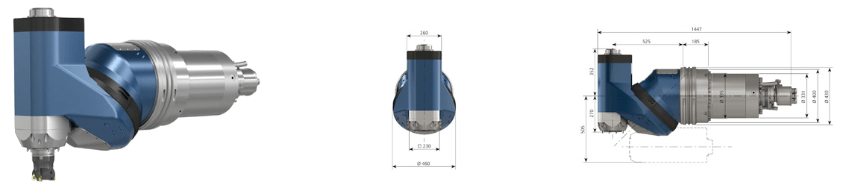

Universal Milling head

The universal milling head allows for precise machining of workpieces due to its compact design and ability to reach both the lowest horizontal and highest vertical machining space. It is ideal for horizontal machine tools in combination with rotary table system. It offers the best power density on the market. It uses a high torque mechanical transmission spindle which can handle even hard to cut materials.

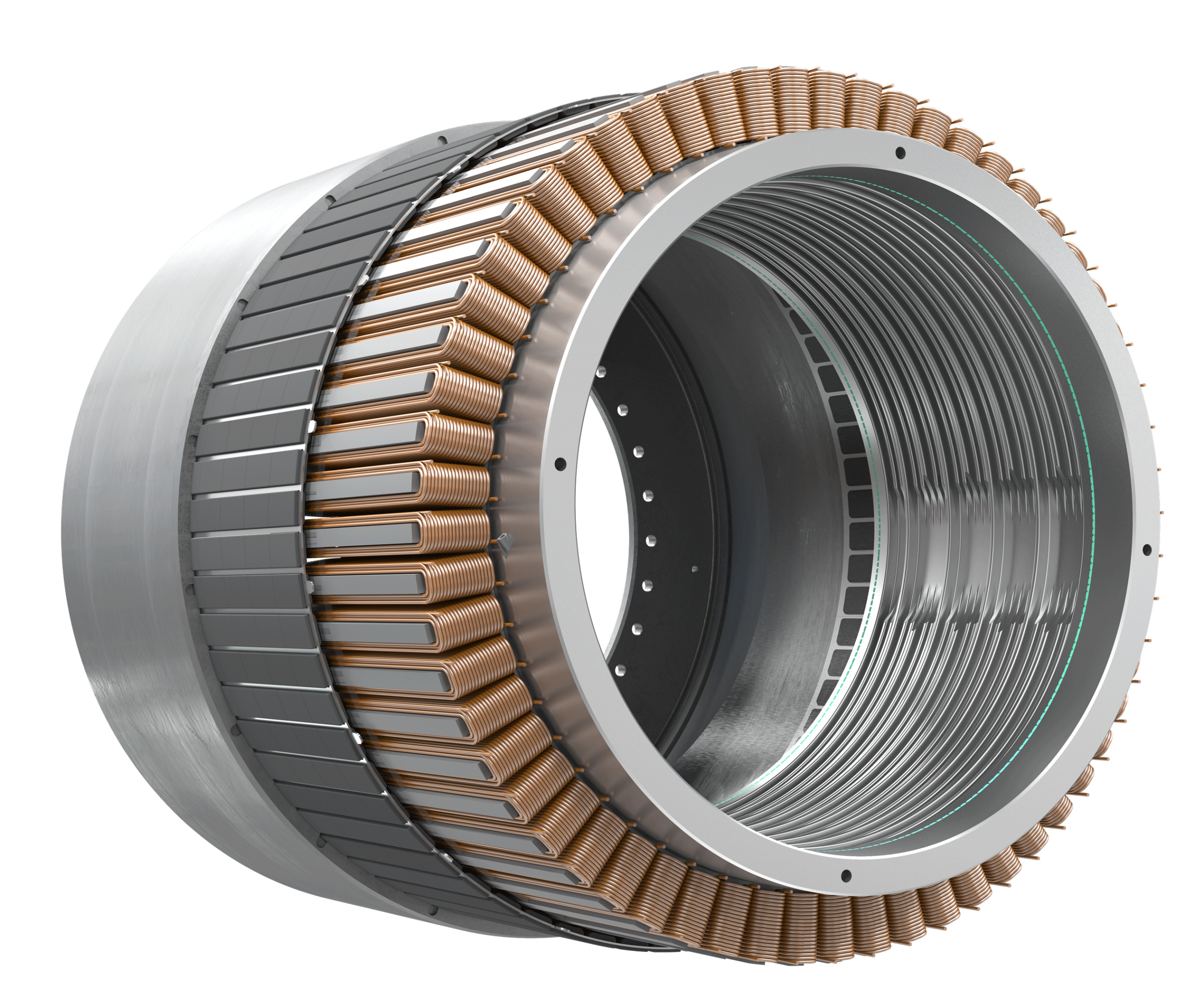

ULTRA-HIGH-TORQUE

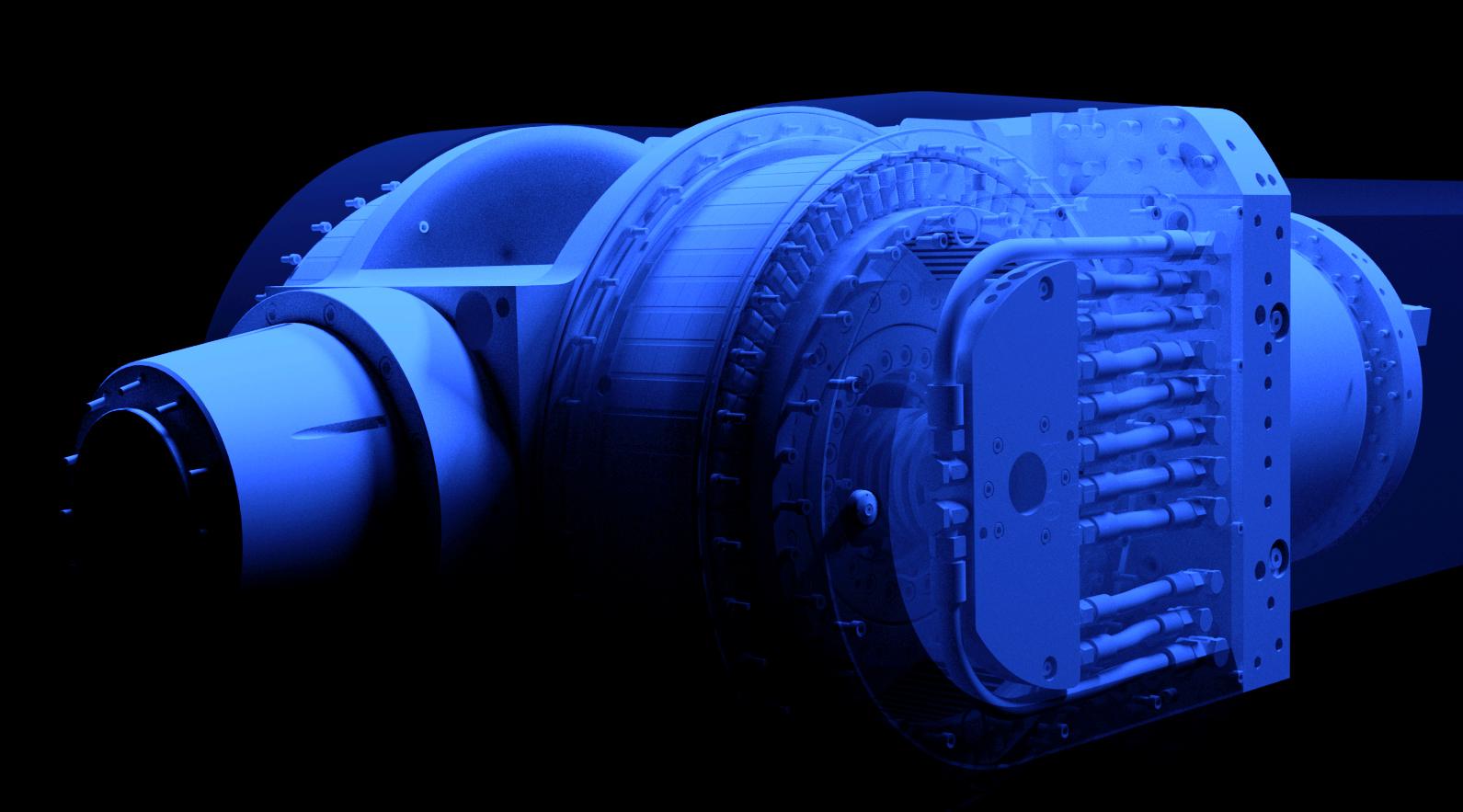

The new direct drive milling heads from CyTec utilize the advantages of a new generation of torque motors with advanced cooling technology.

This enables a power increase of 30% and higher efficiency.

This allows for higher power and torque, enabling more efficient simultaneous machining.

This leads to an increase in dynamic milling performance.

Milling head HD PDF

FSW PDF

Milling head PDF

OVERVIEW PDF

Deep hole drill unit PDF

| Factor | Description |

|---|---|

| Speed | The maximum speed rotatate the axis of milling head |

| Power | The amount of power that the milling head can deliver to the cutting tool |

| Tolerance | The degree to which the milling head can maintain the precise position and alignment of the cutting tool |

| Capacity | The size and weight of the workpiece that the milling head can handle |

| Tool holding | The way in which the cutting tool is held in the milling head |

| Compatibility | Compatibility of the milling head with the rest of the machine |

| Additional features | Additional features such as tool measurement and automatic tool change |

CYTEC's processing heads in Heavy Duty (HD) version feature high-torque milling spindles and a rigid design for processing high-strength materials.

Additionally, CYTEC's milling heads achieve high torque through powerful motors and integrated gearboxes, and they offer even higher torque options with gear drives. Despite high torque, all CYTEC's milling heads are known for precision and reliability. CYTEC's Torque motors provide optimal control and overload capacity, and proven solutions are used for axis clamping during heavy machining.

Fork Milling head

has the ability to simultaneously position the cutter in space. This is achieved by controlling the A-axis and the C-axis simultaneously. By combining the movements of the two axes, the Fork Milling head can position the cutter in any desired position in space, allowing for complex and precise cuts to be made on the workpiece.

This type of cutter is particularly suitable for the production of complex tools and shapes where high precision and flexibility is required.

| NANO | Our smallest model containing our ultra-compact direct drive technology | |

| S-Series | Slime-line as perfect entry-level choice in steel-milling. | |

| S-Series HD | Compact, light, enormously strong. The ideal choice for the machining of structural components, that are difficult to access. | |

| M-SERIES | 5 axes milling, turning, grinding. With a large spindle selection for every application,up to 40 kW. | |

| M-SERIES HD | At home in heavy machining, but due to its flexibility the ideal all-rounder for finish machining. | |

| G-SERIES | Best power density on the market. Perfect for aerospace, engineering and commercial vehicle production. | |

| G-SERIES HD | Sheer power and highly dynamic at the same time - without compromises from rough to fine 5-axis machining. | |

| T-SERIES | A true powerhouse that meets 100% of the requirements needed to machine complex workpieces made of high-strength materials, also for the aerospace industry. | |

Universal Milling head

The universal milling head allows for precise machining of workpieces due to its compact design and ability to reach both the lowest horizontal and highest vertical machining space. It is ideal for horizontal machine tools in combination with rotary table system. It offers the best power density on the market. It uses a high torque mechanical transmission spindle which can handle even hard to cut materials.

| M-SERIES 45° | Ideal for horizontal machine tools in combination with rotary table system. Slim design and with a large spindle selection for every application. |

| M-SERIES 45° HD | Ideal for horizontal machine tools in combination with rotary table system. Best power density on the market. |

| G-SERIES 45° | Ideal for horizontal machine tools in combination with rotary table system. Best power density on the market. |

Universal Milling head

The universal milling head allows for precise machining of workpieces due to its compact design and ability to reach both the lowest horizontal and highest vertical machining space. It is ideal for horizontal machine tools in combination with rotary table system. It offers the best power density on the market. It uses a high torque mechanical transmission spindle which can handle even hard to cut materials.

| M-SERIES 45° | Suitable for horizontal and vertical machine tools. |

| M-SERIES 45° HD | The universal milling head with maximum flexibility, ideal in the Tool Center. Simultaneous or in high-precision positioning mode with 0.0005°. |

| P-SERIES | Economical-flexible-light. High torque for simultaneous milling with hydraulic locking of the axes. |